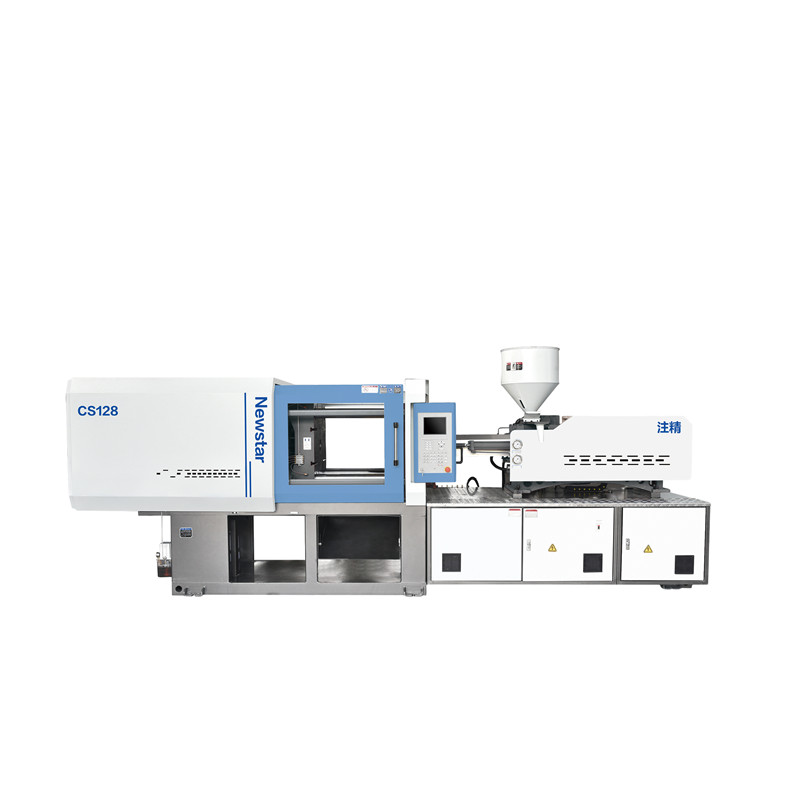

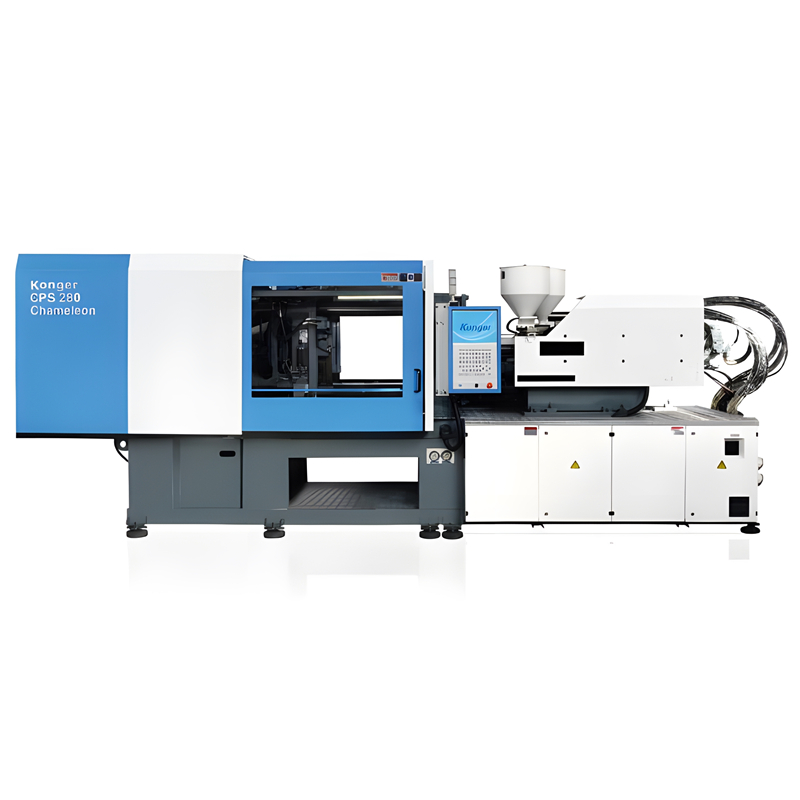

China wholesale Clamp Molding Supplier - Chameleon-CS Series Plastic Injection Molding Machine – KONGER

China wholesale Clamp Molding Supplier - Chameleon-CS Series Plastic Injection Molding Machine – KONGER

China wholesale Clamp Molding Supplier - Chameleon-CS Series Plastic Injection Molding Machine – KONGER Detail:

Product advantages

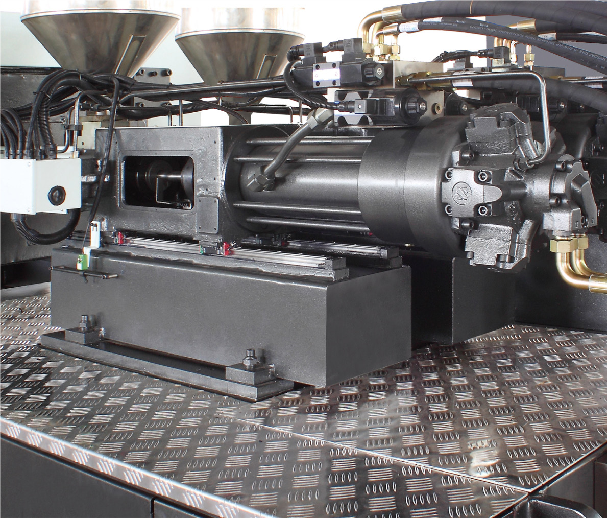

● Efficiently Servo Gear transmission structure keep rotating high speed with stable and precise position.

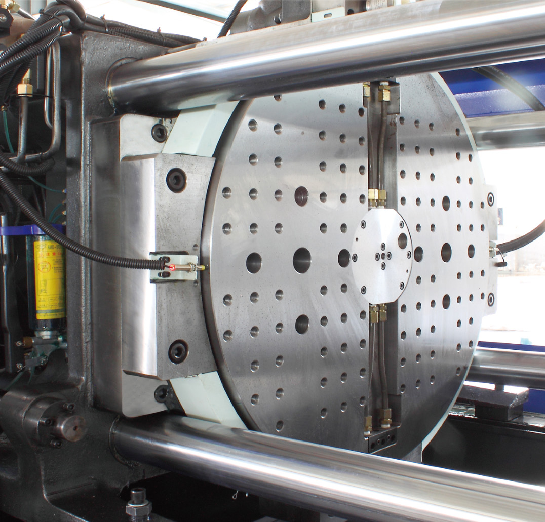

● Graphite copper sleeve used on tie-bar and eject guide bar. Graphite copper block pads used on movement plate and end plate keep the fast and precise moulds open position.

● Reciprocating 180 degree rotation table on movement plate. Can setup two moulds produce the two different color products.

● Single injection cylinder keep injection more stable and precision.

● Low friction drag with precise guide because of injection linear guide.

● Special design all screw L:D=20:1 for all size injection unit setup easy changeable.Can match all customer special requirement.

SPECIFICATION

| DESCRIPTION | unit | CPS150 axis | CPS230 axis | ||||||||||||||||||||||

| INJECTION UNIT | A | B | A | B | A | B | A | B | |||||||||||||||||

| Screw Diameter | mm | 28 | 32 | 28 | 32 | 32 | 40 | 32 | 40 | ||||||||||||||||

| Screw LD rotio | L/D | 22.5 | 22.5 | 22.5 | 22.5 | 22.5 | 20 | 22.5 | 20 | ||||||||||||||||

| Shot volume | cm³ | 108 | 141 | 108 | 141 | 141 | 220 | 141 | 220 | ||||||||||||||||

| Shot welight(PS) | g | 98 | 128 | 98 | 128 | 128 | 200 | 128 | 200 | ||||||||||||||||

| oz | 3.5 | 4.5 | 3.5 | 4.5 | 4.5 | 7.1 | 4.5 | 7.1 | |||||||||||||||||

| Injection pressure | Bar | 2699 | 2066 | 2699 | 2066 | 2640 | 1690 | 2640 | 1690 | ||||||||||||||||

| njection rate | cm³/s | 79 | 83 | 79 | 83 | 83 | 129 | 83 | 129 | ||||||||||||||||

| Plosticizing capooity | g/s | 9 | 10 | 9 | 10 | 12 | 18 | 12 | 18 | ||||||||||||||||

| injection stroke | mm | 175 | 175 | 175 | 175 | 175 | 175 | 175 | 175 | ||||||||||||||||

| Injection speed | mm/s | 120 | 120 | 120 | 120 | 103 | 103 | 103 | 103 | ||||||||||||||||

| Max screw speed | r/min | 221 | 221 | 221 | 221 | 221 | 221 | 221 | 221 | ||||||||||||||||

| CLAMPING UNIT | |||||||||||||||||||||||||

| Clamping force | KM | 1500 | 2300 | ||||||||||||||||||||||

| Opening stroke | mm | 445 | 475 | ||||||||||||||||||||||

| Space between tle bars | mm | 470×470 | 520×520 | ||||||||||||||||||||||

| Mold height (Max-Min) | mm | 180~ 520 | 200~ 530 | ||||||||||||||||||||||

| Ejector stroke | mm | 70 | 80 | ||||||||||||||||||||||

| Ejector stroke | mm | 140 | 140 | ||||||||||||||||||||||

| Number of ejector | Pcs | lX2 | lX2 | ||||||||||||||||||||||

| Distance Berrel Centers | mm | 280 | 300 | ||||||||||||||||||||||

| POWER UNIT | |||||||||||||||||||||||||

| Systerm pressure | Bar | 160 | 160 | ||||||||||||||||||||||

| Pump motor | KW | 14 | 14 | 14 | 14 | ||||||||||||||||||||

| Heating capacity | KW | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | ||||||||||||||||

| Number of temp zones | 2X4 | 2X4 | |||||||||||||||||||||||

| OTHERS | |||||||||||||||||||||||||

| Oil tank capacity | L | 400 | 460 | ||||||||||||||||||||||

| Machine imension(L xWxH) | m | 5.0X1.43X2.1 | 5.68X1.53X 2.14 | ||||||||||||||||||||||

| Machine weight | t | 6 | 7 | ||||||||||||||||||||||

| Hopper capacity | kg | 25 | 25 | 25 | 25 | ||||||||||||||||||||

| DESCRIPTION | unit | CPS170 | CPS280 | CPS320 | CPS400 | CPS450 | CPS850 | ||||||||||||||||||

| INJECTION UNIT | A | B | A | B | A | B | A | B | A | B | A | B | A | B | A | B | A | B | A | B | A | B | A | B | |

| Screw Diameter | mm | 28 | 32 | 28 | 32 | 28 | 32 | 32 | 40 | 32 | 40 | 40 | 45 | 40 | 45 | 40 | 45 | 40 | 45 | 40 | 45 | 40 | 50 | 50 | 55 |

| Screw LD rotio | L/D | 22.5 | 22.5 | 22.5 | 22.5 | 22.5 | 22.5 | 22.5 | 20 | 22.5 | 20 | 23 | 20.5 | 23 | 20.5 | 23 | 20.5 | 23 | 20.5 | 23 | 20.5 | 23 | 20.5 | 20 | 20 |

| Shot volume | cm³ | 108 | 141 | 108 | 141 | 108 | 141 | 141 | 219 | 141 | 219 | 283 | 358 | 283 | 358 | 283 | 358 | 283 | 358 | 283 | 358 | 283 | 442 | 442 | 535 |

| Shot welight(PS) | g | 98 | 128 | 98 | 128 | 98 | 128 | 128 | 199 | 128 | 199 | 257 | 326 | 257 | 326 | 257 | 326 | 257 | 326 | 257 | 326 | 257 | 402 | 402 | 486 |

| oz | 3.5 | 4.5 | 3.5 | 4.5 | 3.5 | 4.5 | 4.5 | 7 | 4.5 | 7 | 9.1 | 11.5 | 9.1 | 11.5 | 9.1 | 11.5 | 9.1 | 11.5 | 9.1 | 11.5 | 9.1 | 14.2 | 14.2 | 17.2 | |

| Injection pressure | Bar | 2699 | 2066 | 2699 | 2066 | 2699 | 2066 | 2066 | 1322 | 2066 | 1322 | 1960 | 1549 | 1960 | 1549 | 1960 | 1549 | 1960 | 1549 | 1960 | 1549 | 1960 | 1254 | 1638 | 1354 |

| njection rate | cm³/s | 79 | 83 | 79 | 83 | 99 | 121 | 121 | 112 | 131 | 141 | 171 | 216 | 171 | 216 | 171 | 216 | 218 | 274 | 218 | 274 | 218 | 340 | 326 | 394 |

| Plosticizing capooity | g/s | 9 | 10 | 9 | 10 | 11 | 12 | 12 | 18 | 12 | 18 | 29 | 29 | 29 | 29 | 29 | 29 | 29 | 29 | 29 | 29 | 27 | 48 | 48 | 59 |

| injection stroke | mm | 175 | 175 | 175 | 175 | 175 | 175 | 175 | 175 | 175 | 175 | 225 | 225 | 225 | 225 | 225 | 225 | 225 | 225 | 225 | 225 | 225 | 225 | 225 | 225 |

| Injection speed | mm/s | 120 | 120 | 120 | 120 | 150 | 150 | 150 | 150 | 190 | 190 | 136 | 136 | 136 | 136 | 136 | 136 | 173 | 173 | 173 | 173 | 173 | 173 | 166 | 166 |

| Max screw speed | r/min | 221 | 221 | 221 | 221 | 250 | 250 | 250 | 250 | 280 | 280 | 250 | 250 | 250 | 250 | 250 | 250 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| CLAMPING UNIT | |||||||||||||||||||||||||

| Clamping force | KM | 1700 | 2800 | 3200 | 4000 | 4500 | 8500 | ||||||||||||||||||

| Opening stroke | mm | 445 | 460 | 460 | 600 | 600 | 1000 | ||||||||||||||||||

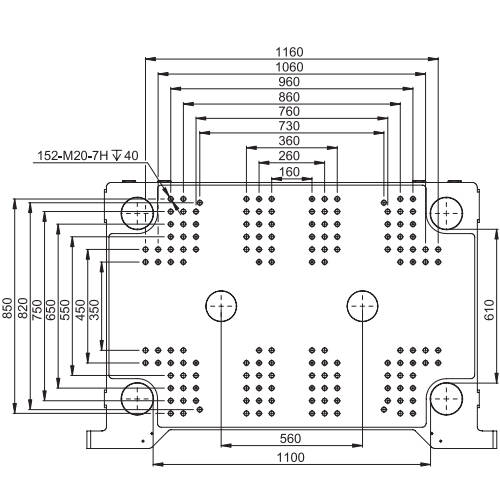

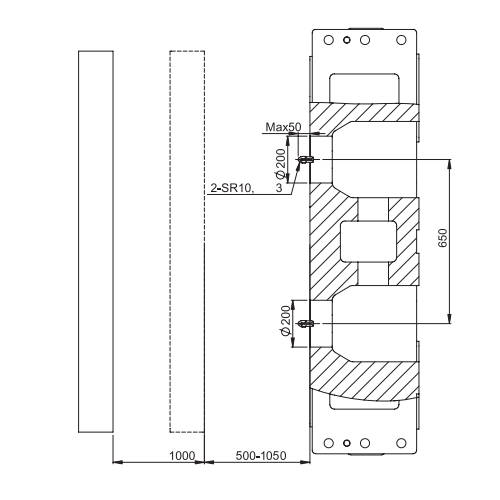

| Space between tle bars | mm | 700 X 440 | 910 X 570 | 910 X 570 | 1100X610 | 1100X610 | 1060X1010 | ||||||||||||||||||

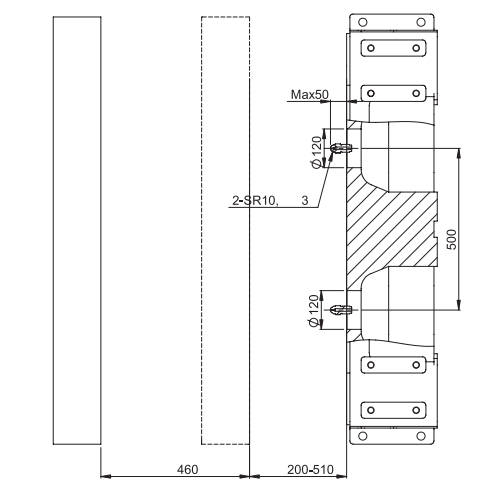

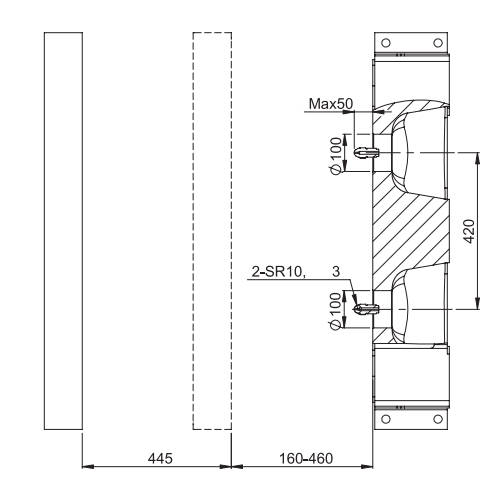

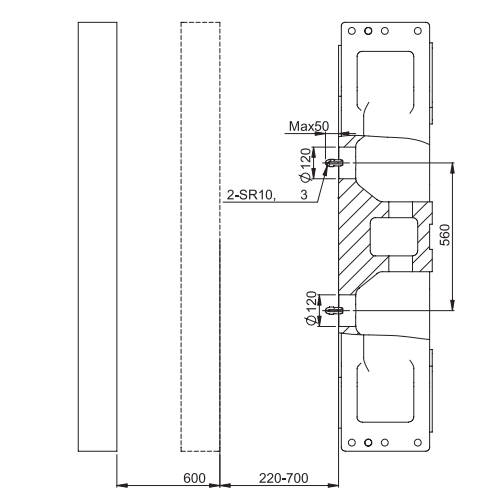

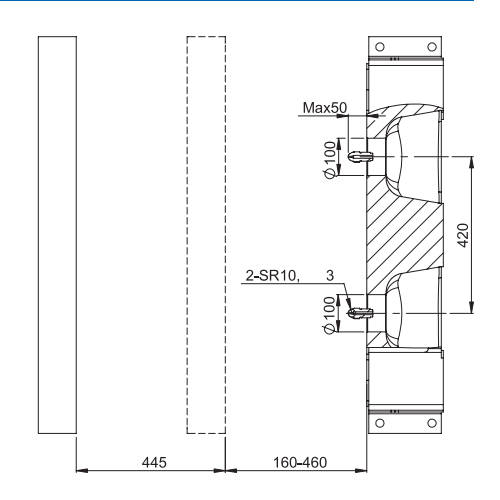

| Die Height(Min-Max) | mm | 160~ 460 | 200~ 510 | 200~ 510 | 220~ 700 | 220~ 700 | 500~ 1050 | ||||||||||||||||||

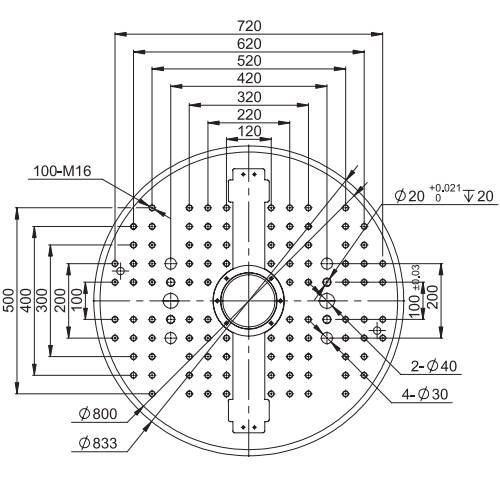

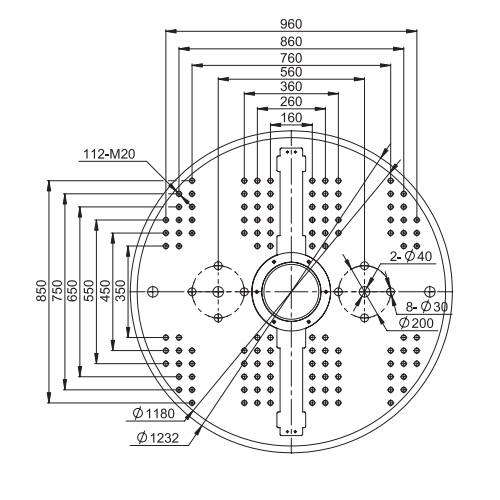

| Rotary Table Diameter | mm | 800 | 1000 | 1020 | 1150 | 1180 | 1530 | ||||||||||||||||||

| Ejector stroke | mm | 100 | 140 | 140 | 140 | 140 | 130 | ||||||||||||||||||

| Ejector force | Pcs | 38X2 | 53X2 | 53X2 | 70X2 | 70X2 | 70X2 | ||||||||||||||||||

| Number of ejector | mm | 3X2 | 3X2 | 3X2 | 5X2 | 5X2 | 5X2 | ||||||||||||||||||

| Distance Berrel Centers | 420 | 500 | 500 | 560 | 560 | 650 | |||||||||||||||||||

| POWER UNIT | |||||||||||||||||||||||||

| Systerm pressure | Bar | 160 | 160 | 160 | 160 | 160 | 160 | ||||||||||||||||||

| Pump motor | KW | 14 | 14 | 18.2 | 18.2 | 23 | 23 | 23 | 23 | 28.3 | 28.3 | 28.3 | 36.7 | ||||||||||||

| Heating capacity | KW | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | 12.3 | 12.3 | 6.8 | 6.8 | 12.3 | 12.3 | 12.3 | 12.3 | 12.3 | 12.3 | 12.3 | 12.3 | 17.3 | 17.3 |

| Number of temp zones | 2X4 | 2X4 | 2X4 | 2X4 | 2X4 | 2X5 | |||||||||||||||||||

| OTHERS | |||||||||||||||||||||||||

| Oil tank capacity | L | 400 | 460 | 500 | 650 | 700 | 1100 | ||||||||||||||||||

| Machine imension(L xWxH) | m | 5.0X1.76X 2.1 | 5.0X1.76X 2.1 | 6.1X2.1X2.2 | 6.8X2.37X2.3 | 7.0X2.0X2.0 | 11.2X3.05X2.75 | ||||||||||||||||||

| Machine weight | t | 7.1 | 12 | 12.5 | 20 | 20.5 | 48 | ||||||||||||||||||

| Hopper capacity | kg | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | ||||||||||||

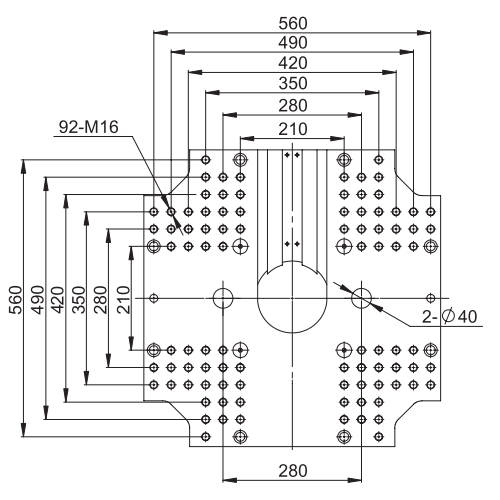

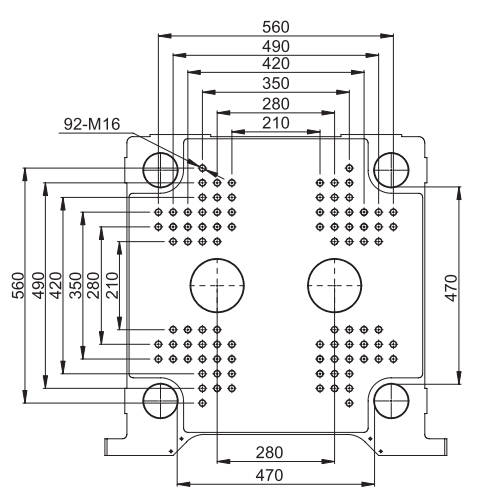

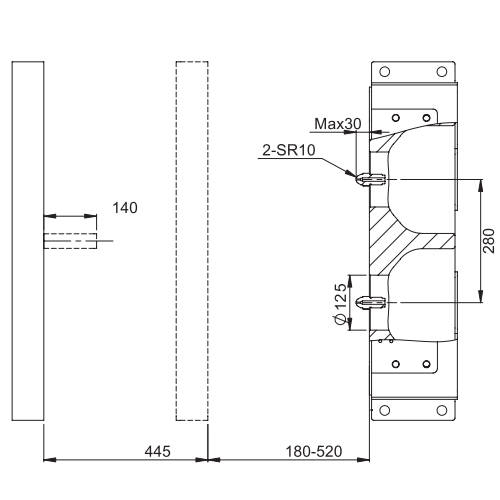

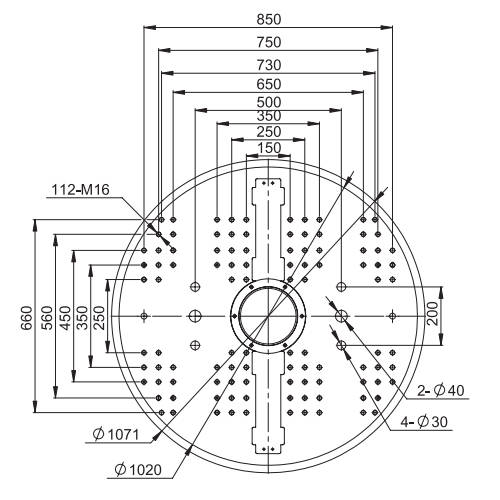

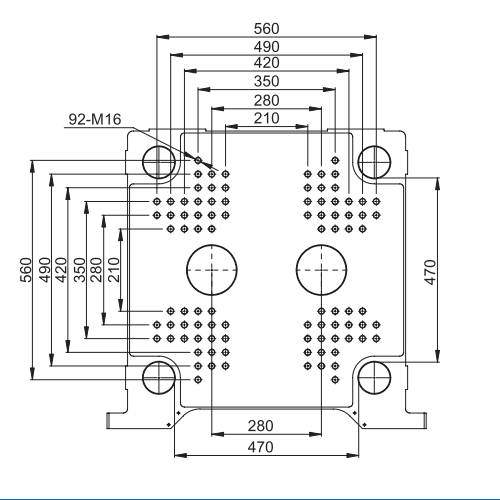

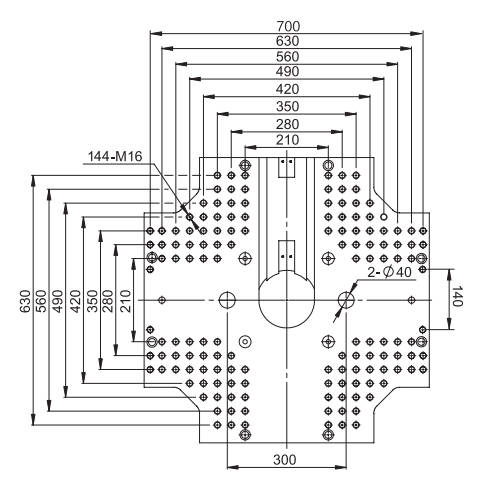

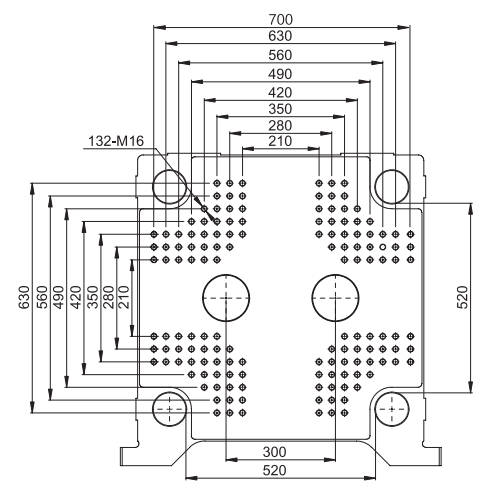

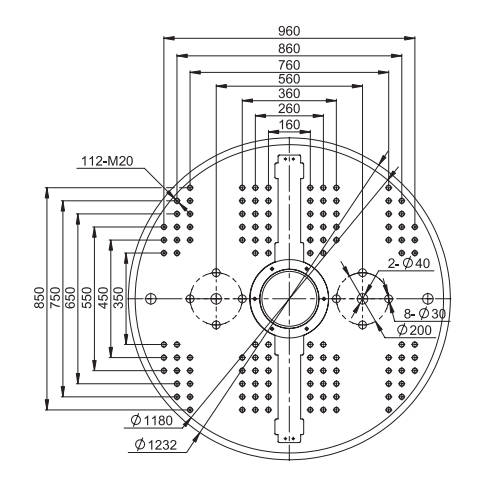

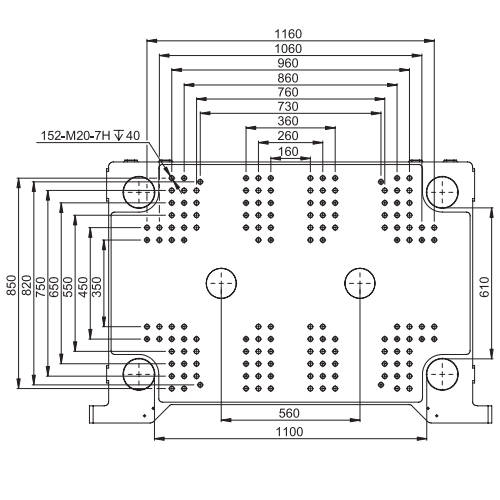

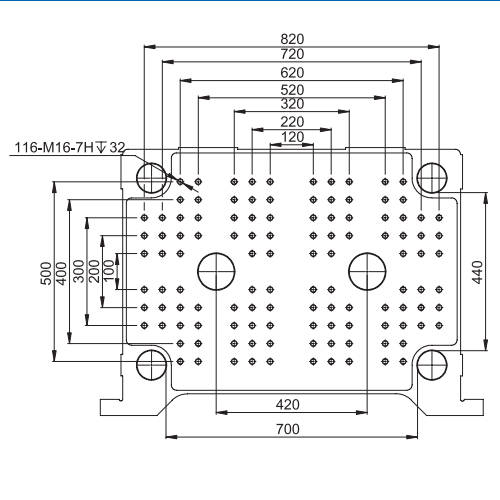

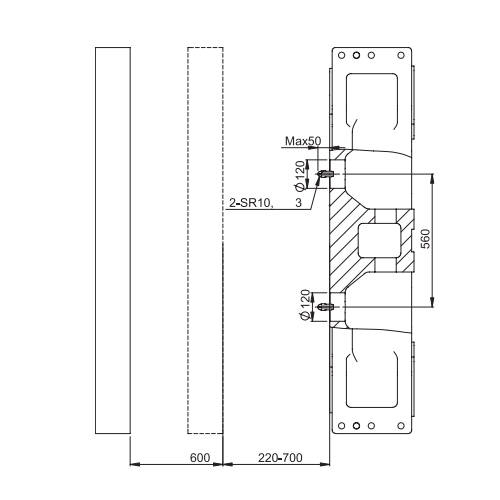

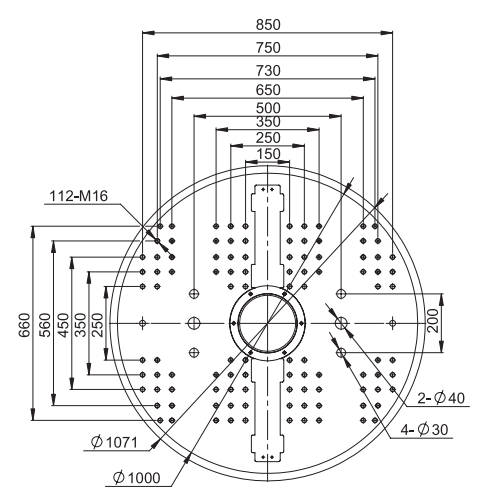

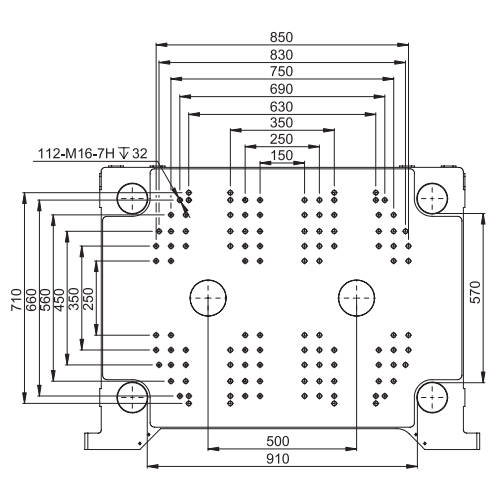

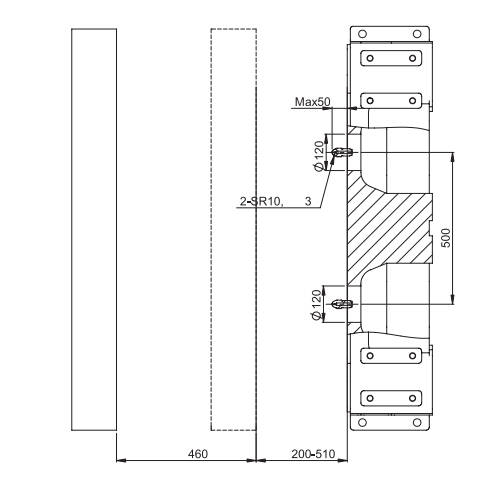

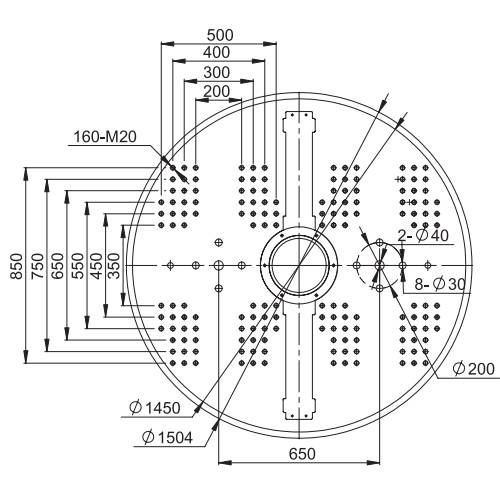

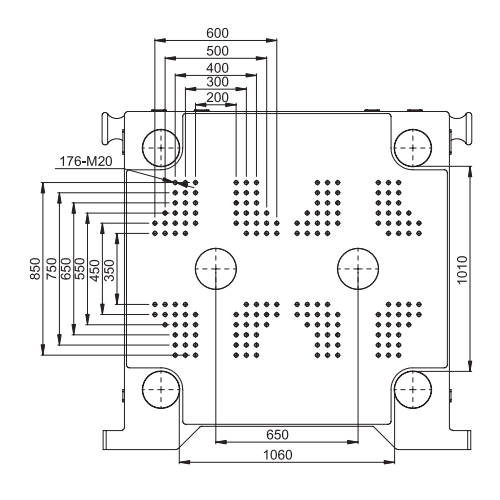

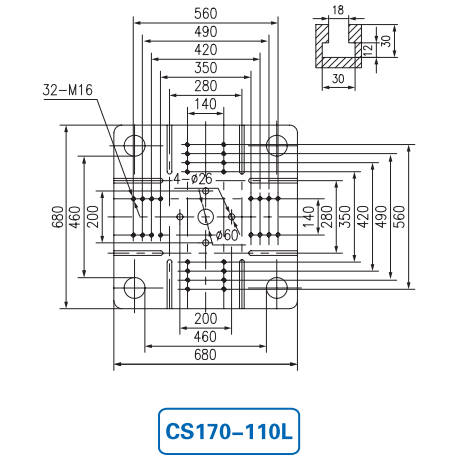

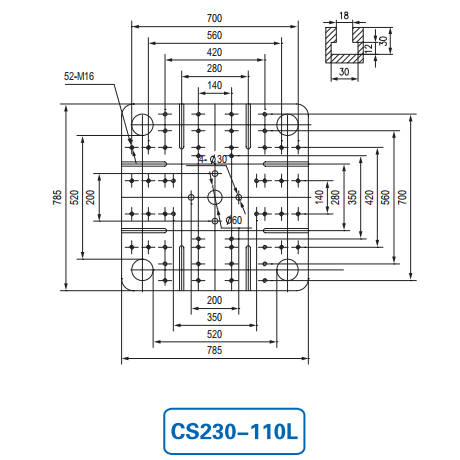

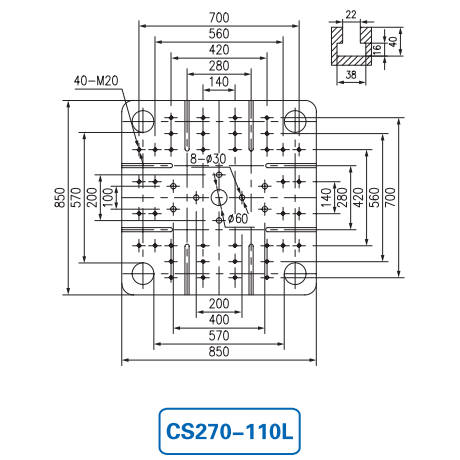

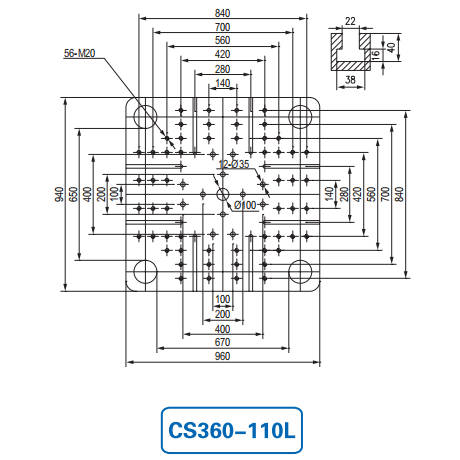

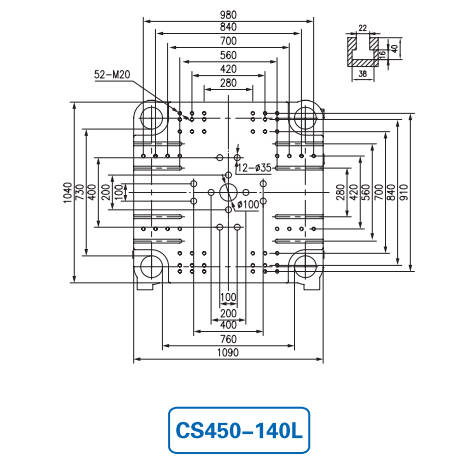

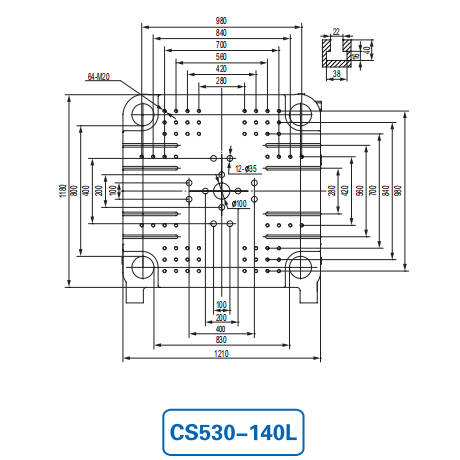

Template plane diagram

L model clean two color

● The two injection unit be L design for clean two color.

● Reciprocating 180 degree rotation table on movement plate.Can setup one moulds produce the two different color products.

●Efficiently servo gear transmission structure keep rotating high speed with stable and precise position.

● Multi-plate design can suit for all products requirement rotation table or rotation shaft.

● Without touch the clamp when the turntable running. Can reduce fault because of the abrasion. Precise position before moulds closed keep the moulds safety.

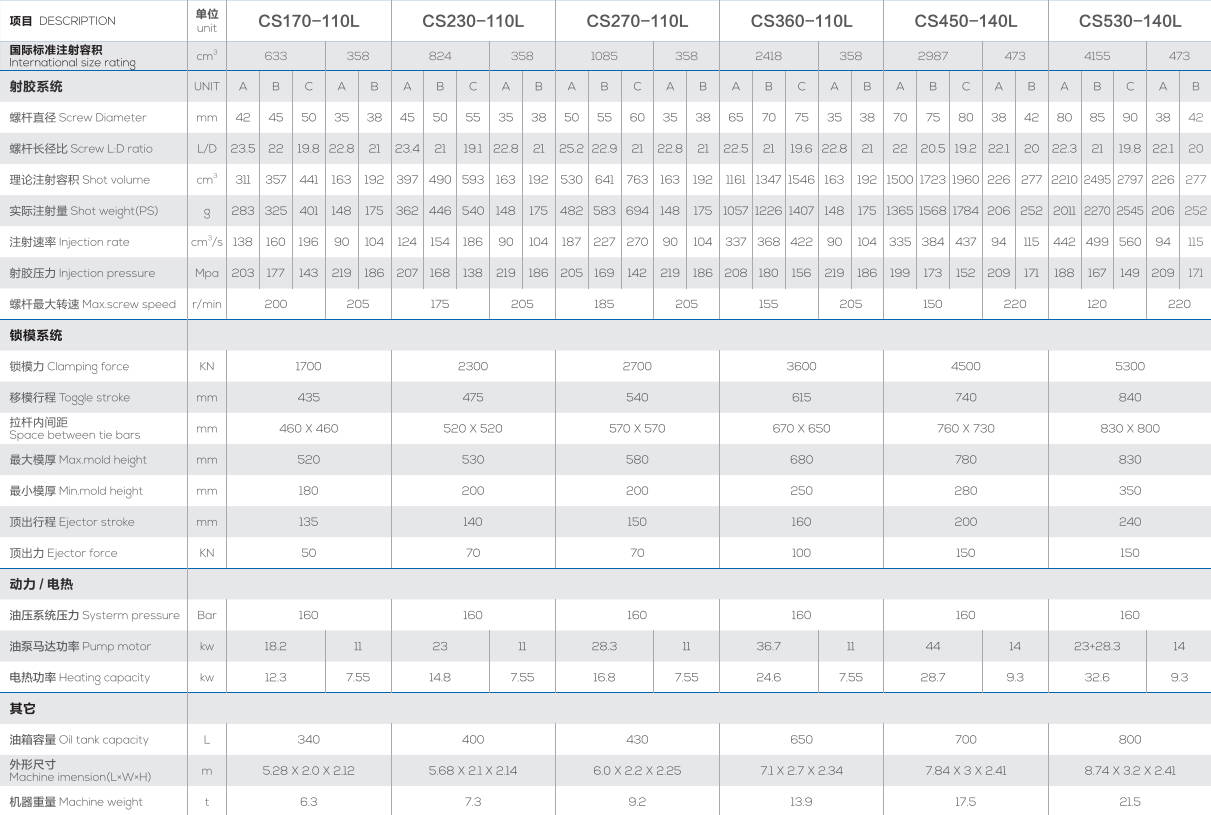

CS230-IIOL

Template size

Product detail pictures:

Related Product Guide:

We consistently execute our spirit of Innovation bringing progress, Highly-quality ensuring subsistence, Administration advertising and marketing gain, Credit history attracting buyers for China wholesale Clamp Molding Supplier - Chameleon-CS Series Plastic Injection Molding Machine – KONGER , The product will supply to all over the world, such as: Mumbai, Latvia, Argentina, The best and original quality for spare parts is a most important factor for transportation. We may stick on supplying original and good quality parts even a little profit earned. God will bless us to do kindness business forever.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.