-

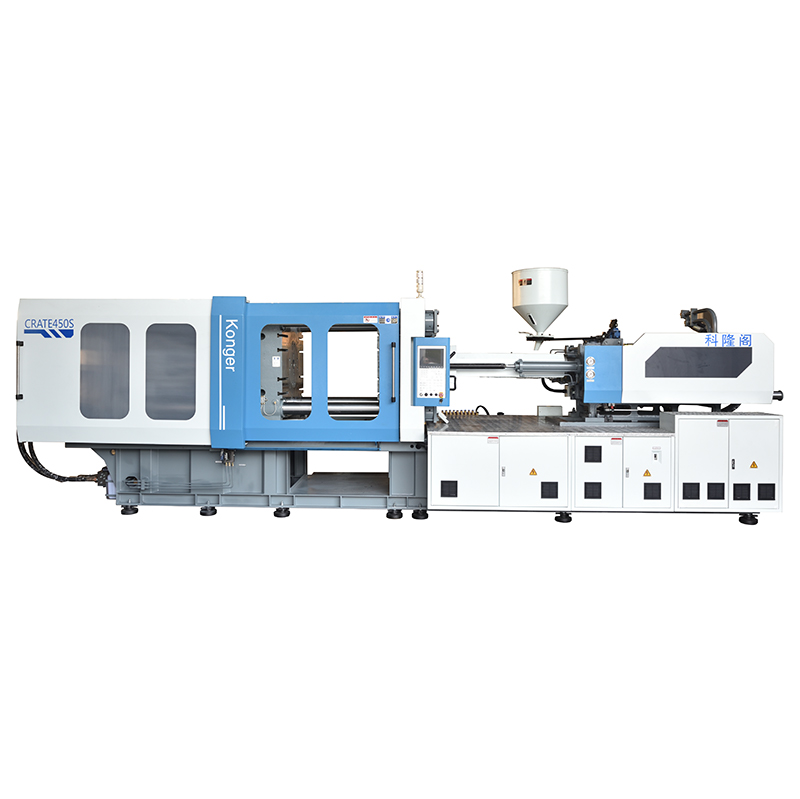

Crate450S Servo Motor Plastic Injection Molding Machine

High-speed clamping unit

The motor automatic clamping unit uses Gear-rack drive, new designed mold closing components by the computer simulation technology. And make the hardening analysis of all the components, optimized internal stress & variable type, in order that the machine moves more stability and smoothly when its running with high speed. It is effective to avoid broke to the plate and tie-bar by the high strength &low stress.

Exelent function& power saving

Konger Crate Series of professional machine uses imported servo systems as the power unit, which has more excellent functions, can save 20%-40% power and 5%-10%energy compared with the traditional fix pump Circulation Box machines more excellent functions.

-

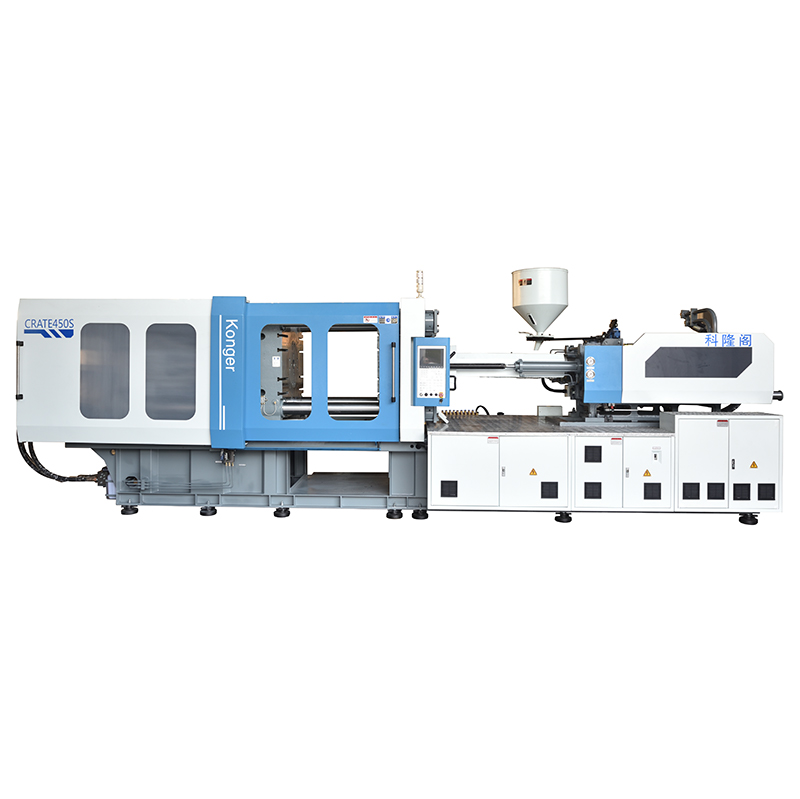

Crate450 Quantitative Pump Series Plastic Injection Molding Machine

High-speed forming technology

The computer controller with the stronger oil pump and servo system is more stable and faster than the other ones. It can shorten the injection moulding period of 15-20%.

Electronic Control Unit

Konger uses the controller with imported high-end professional injection moulding machines, it has a clourful display with a large size and make us comfortably. Besides, Konger uses key electronic componets with the famous brand,such as: Schneider, Omron, Siemens,etc. They has more stable quality and reliable function,its benifit to guarantee normally working of the electronic control unit.