-

-

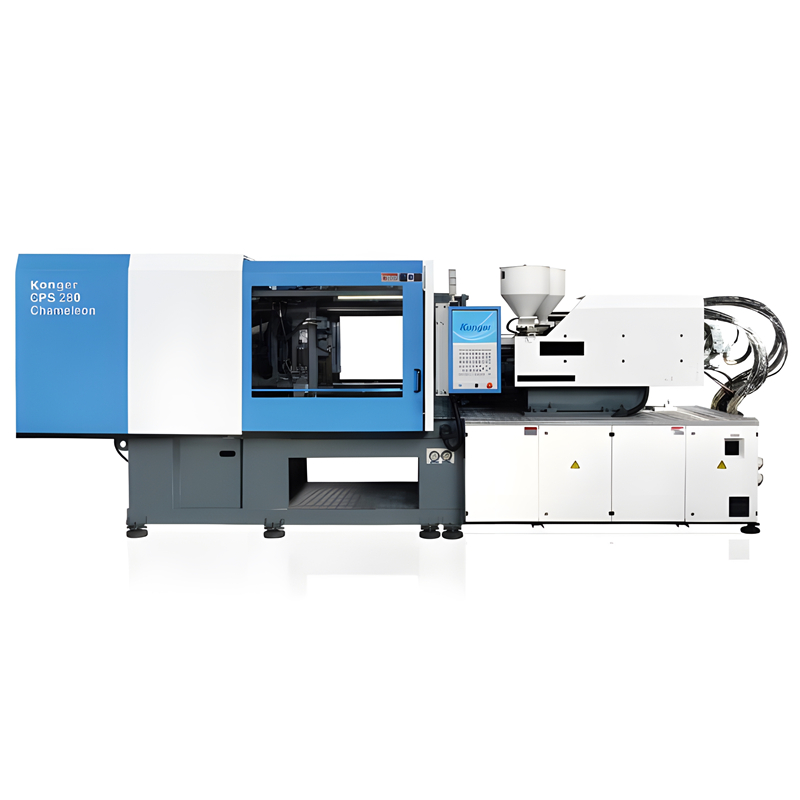

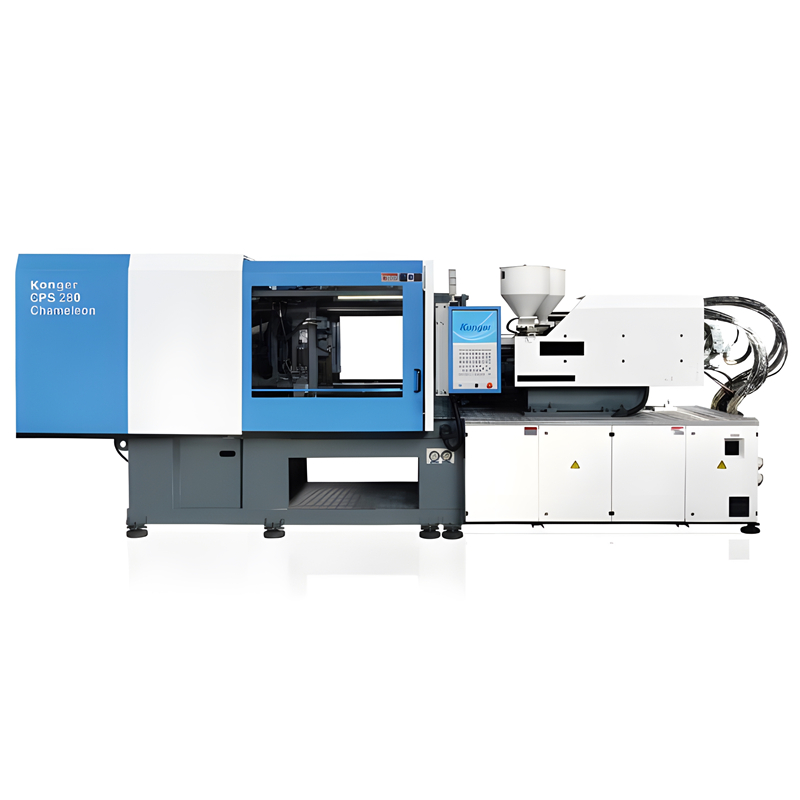

CPS280 CLEAN TWO COLORS Plastic Injection Molding Machine

Without touch the clamp when the turntable running.Canreducefaultbecauseoftheabrasion Precisepositionbeforemouldsclosedkeepthemoulds safety.

Eject force be more stronger because double eject cylinder.

Efficiently Servo Gear transmission structure keep rotating high speed with stable and precise position. Graphite copper sleeve used on tie-bar and eject guide bar.Graphitecopperblockpadsusedonmovement plate and end plate keep the fast and precise moulds open position.

Reciprocating 180 degree rotation table on movement plate.Can setup two moulds produce the two different color products.

Single injection cylinder keep injection more stable and precision.

Low friction drag with precise guide because of injection linear guide.

Special design all screw L:D=20:1 for all size injection unitsetupeasychangeable.canmatchallcustomer special requirement.

-

CMS230-MIXED COLORS Plastic Injection Molding Machine

For different material with different layer.Once times injection instead of the twice times .

Multi-color products lead the best value for customer. Inner material can be using the special material with low injection pressure get more value for customer.

Can produce the single color products and mix two color products.We supply the Multi-function and best solutions. Inner material can be using recycle material or waste material.Can be get more value for customer.

lnner and surface different material of solutions leader products more stronger.

-

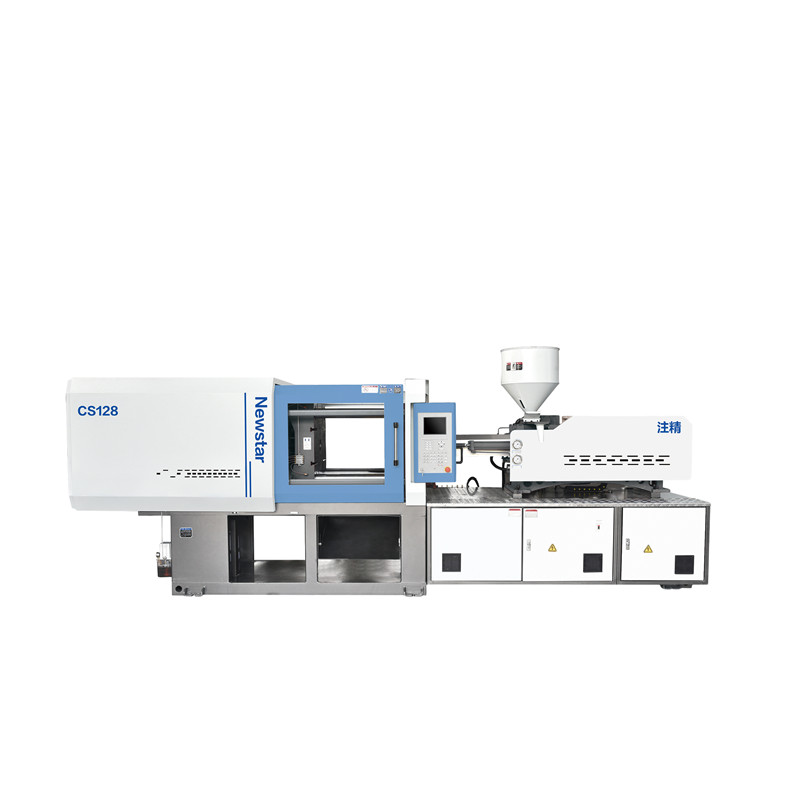

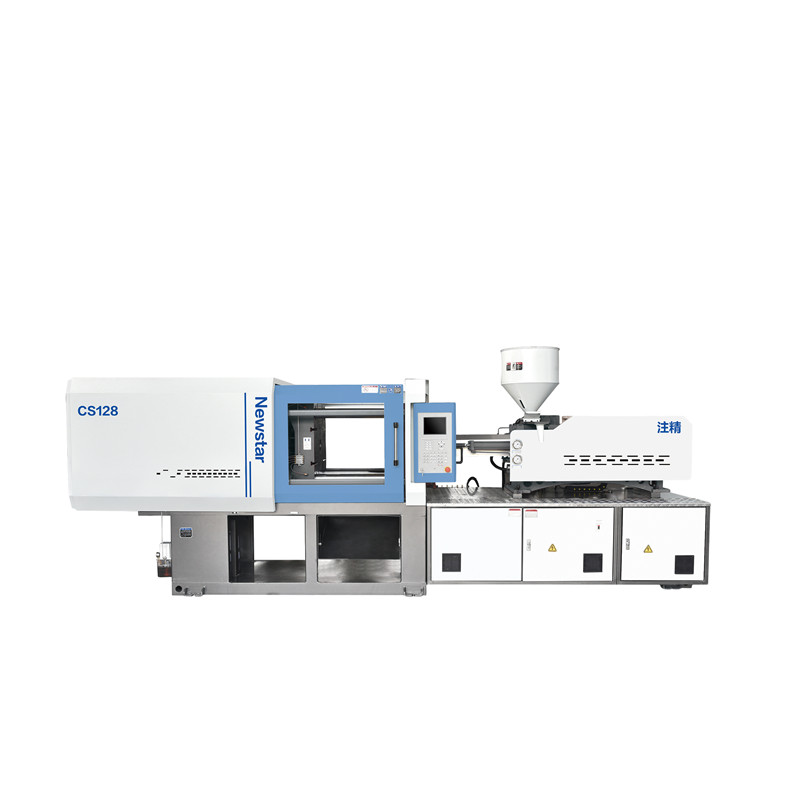

CS128 Newstar Series Plastic Injection molding machine

Excellent molding produce valvestability

The servo driving system has its pressure and flow under close loop control: and compared with traditional injection molders, its molding repetition precision is improved substantiallyRapid response

The servo driver features rapid response whose rapid starting time is improved by 50% compared with traditional injectionHigh performanceV environmental protection

The complete machine features, low operating noise, and even quieter during low-speed operation -

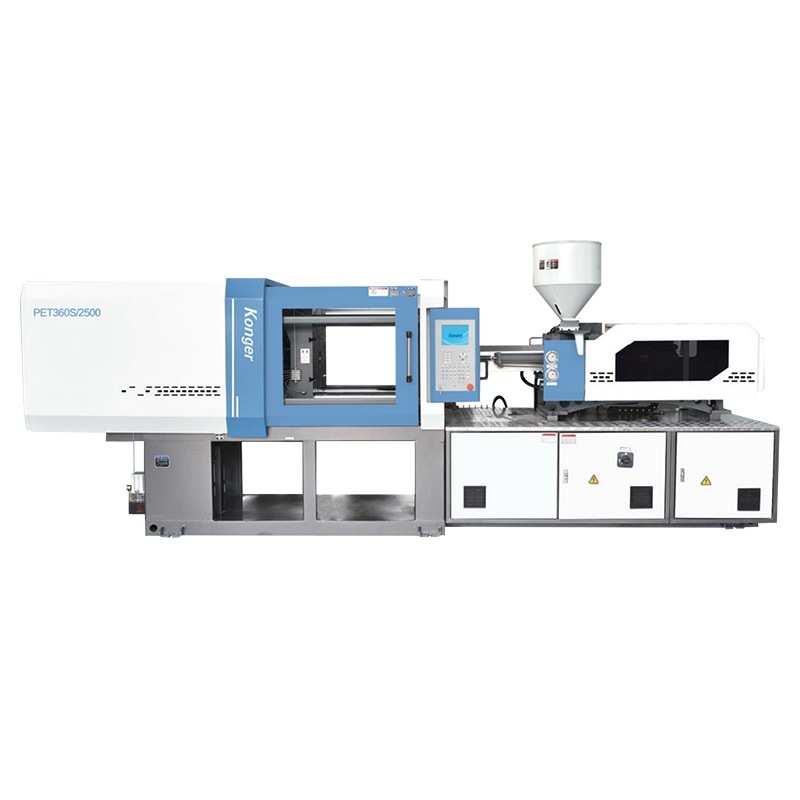

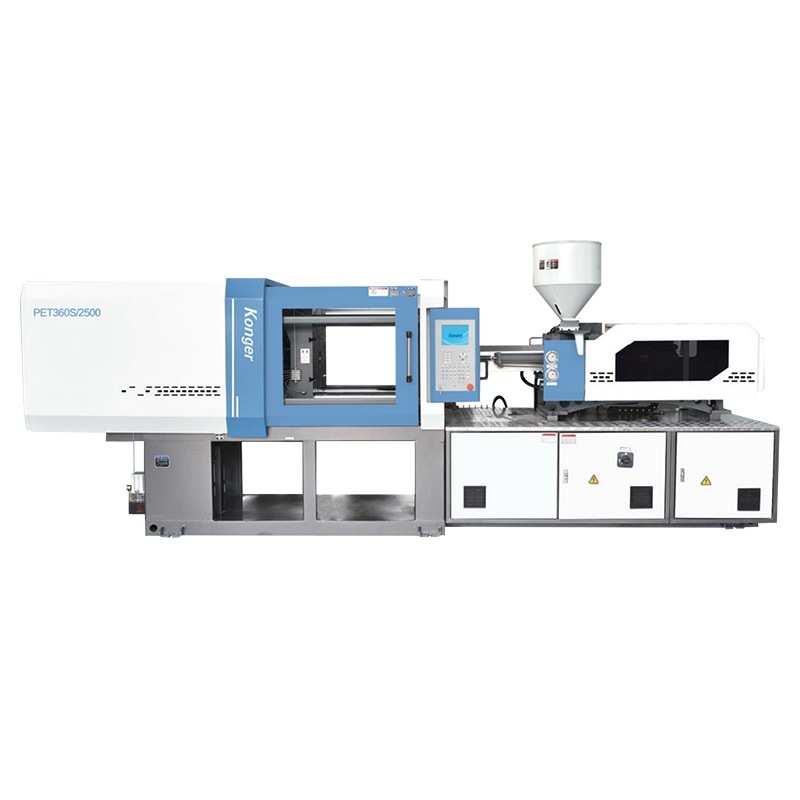

PET360/2500 S6 SERVO MOTOR Plastic Injection Molding Machine

● Special of the PET screw and barrel. Improve the charge speed and injection weight. Reduce the plasticizing temperature and AA. Effectively improve the contraction of the bottle and improve the transparency.

● Variable pump can save 25%–45% power than fix pump.Servo machines can save the 30%–50% power than fix pump.

● Multi-machines model match the different size of the bottle. The maxinjection weight: 5000 gram. More stronger eject force and eject stroke special for PET bottle.

-

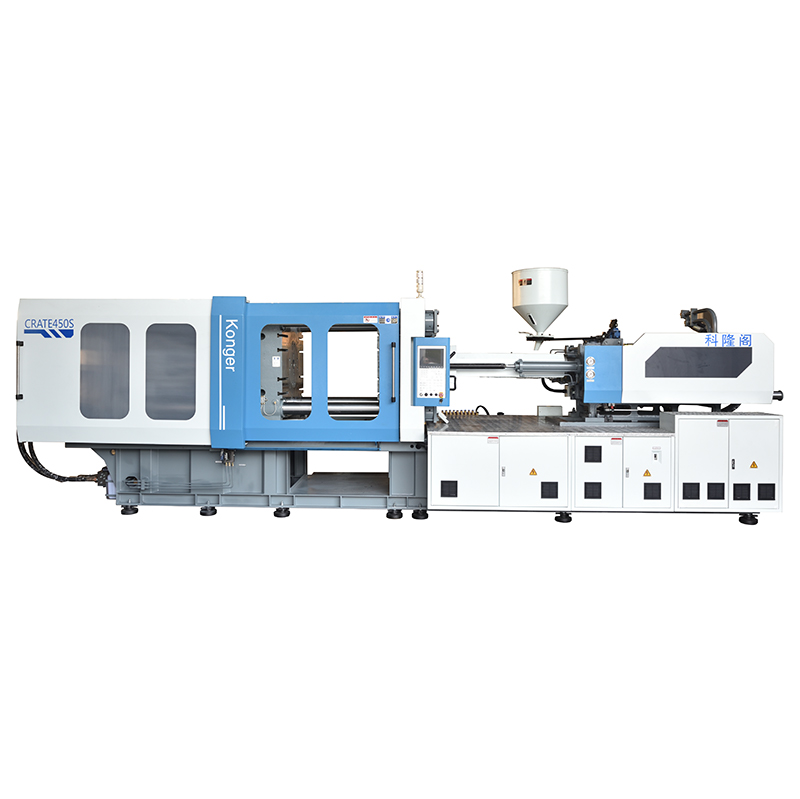

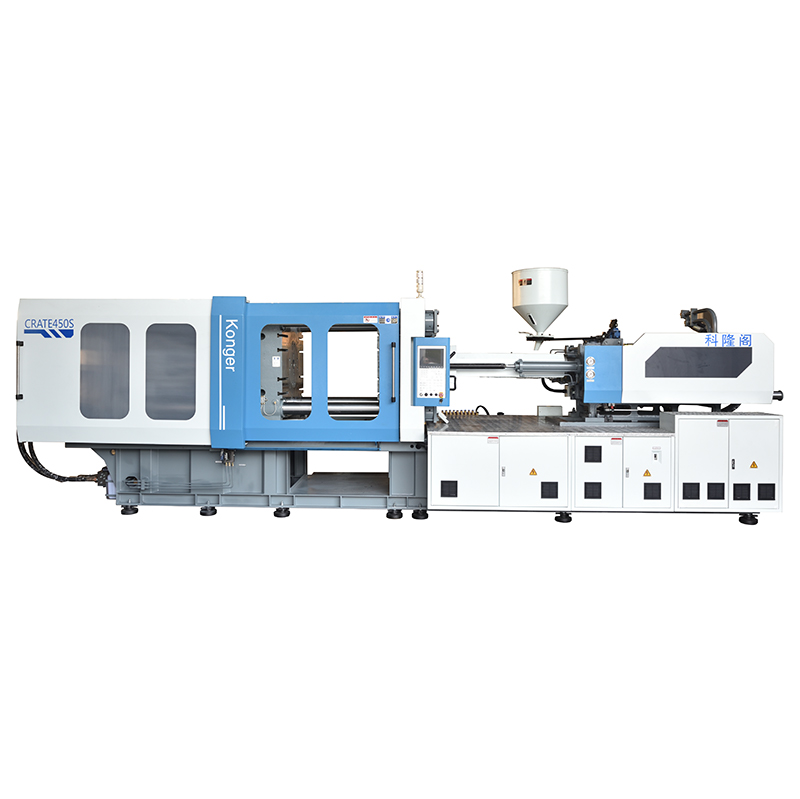

Crate450S Servo Motor Plastic Injection Molding Machine

High-speed clamping unit

The motor automatic clamping unit uses Gear-rack drive, new designed mold closing components by the computer simulation technology. And make the hardening analysis of all the components, optimized internal stress & variable type, in order that the machine moves more stability and smoothly when its running with high speed. It is effective to avoid broke to the plate and tie-bar by the high strength &low stress.

Exelent function& power saving

Konger Crate Series of professional machine uses imported servo systems as the power unit, which has more excellent functions, can save 20%-40% power and 5%-10%energy compared with the traditional fix pump Circulation Box machines more excellent functions.

-

K-TEC170/Dry Plastic Injection Molding Machine

● Save the cost of drying material (according to the size of equipment and raw material products vary).

● Improve the boot time of workers.

● Reduce the pause time of drying material.

● Product color to improve consistency.

● Reduce the product binding line.

● Reduce the chance of burning products.

● Improve the fluidity of plastic raw materials.

● Save the cost of purchasing auxiliary machine (drying equipment).

● Reduce the fear of workers on equipment drying.

● Prevent the plastic in the drying material when the caking and discoloration.

-

Phoenix-230P Half High Speed Plastic Injection Molding Machine

Compared with the traditional injection molding machine, Phoenix /P series has a faster injection speed, which can reach about 150mm/s. It can solve some defects of traditional injection molding machines in the injection process (such as water ripples,etc.);

Can meet customers’ high requirements for precision parts;

With finite element technical analysis platen design, optimizing platen structure, dedicated to fast operation, especially suitable for precision mold usage;

Adopting modular design, the same mold locking mechanism can combine with different specifications of injection mechanisms and screw;

Compared to traditional injection molding machines, it has greater output power.

-

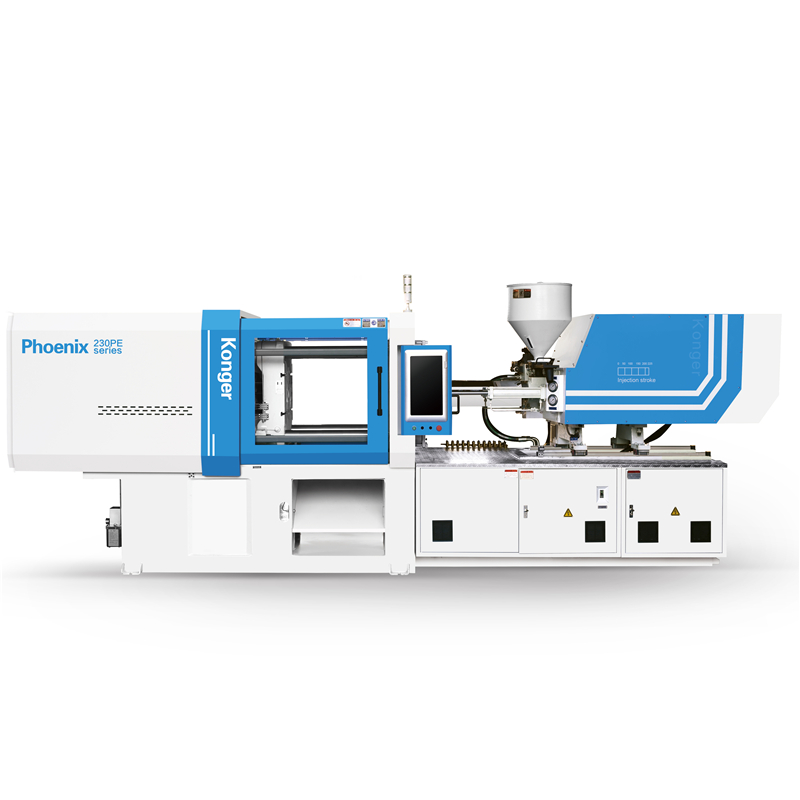

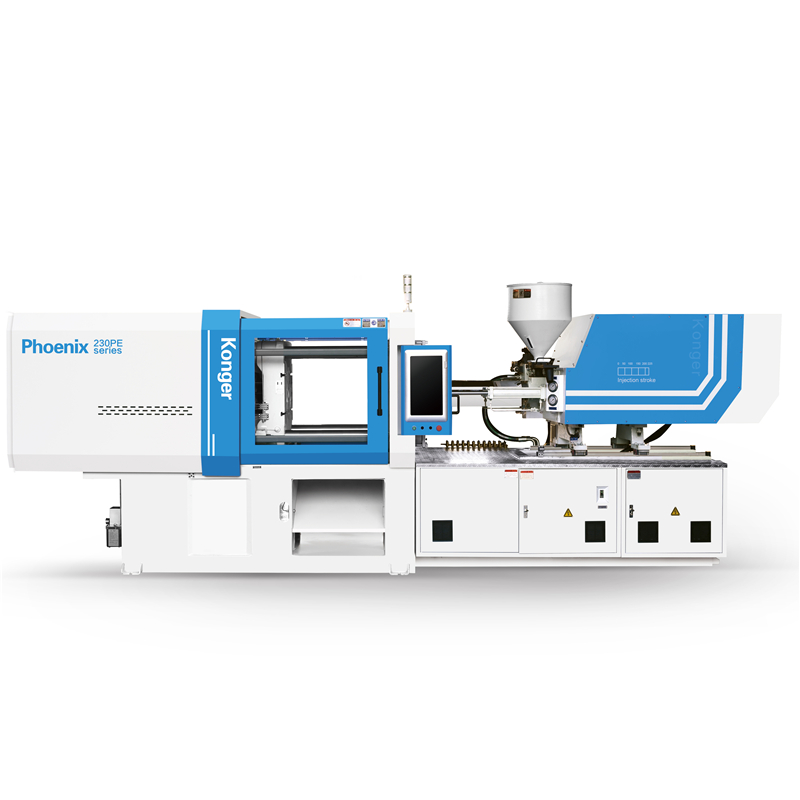

Phoenix-230PE Half High Speed Plastic Injection Molding Machine With Electric Charging

Compared with the traditional injection molding machine, Phoenix /P series has a faster injection speed, which can reach about 150mm/s. It can solve some defects of traditional injection molding machines in the injection process (such as water ripples,etc.);

Can meet customers’ high requirements for precision parts;

With finite element technical analysis platen design, optimizing platen structure, dedicated to fast operation, especially suitable for precision mold usage;

Adopting modular design, the same mold locking mechanism can combine with different specifications of injection mechanisms and screw;

Compared to traditional injection molding machines, it has greater output power.

-

Crate450 Quantitative Pump Series Plastic Injection Molding Machine

High-speed forming technology

The computer controller with the stronger oil pump and servo system is more stable and faster than the other ones. It can shorten the injection moulding period of 15-20%.

Electronic Control Unit

Konger uses the controller with imported high-end professional injection moulding machines, it has a clourful display with a large size and make us comfortably. Besides, Konger uses key electronic componets with the famous brand,such as: Schneider, Omron, Siemens,etc. They has more stable quality and reliable function,its benifit to guarantee normally working of the electronic control unit.

-

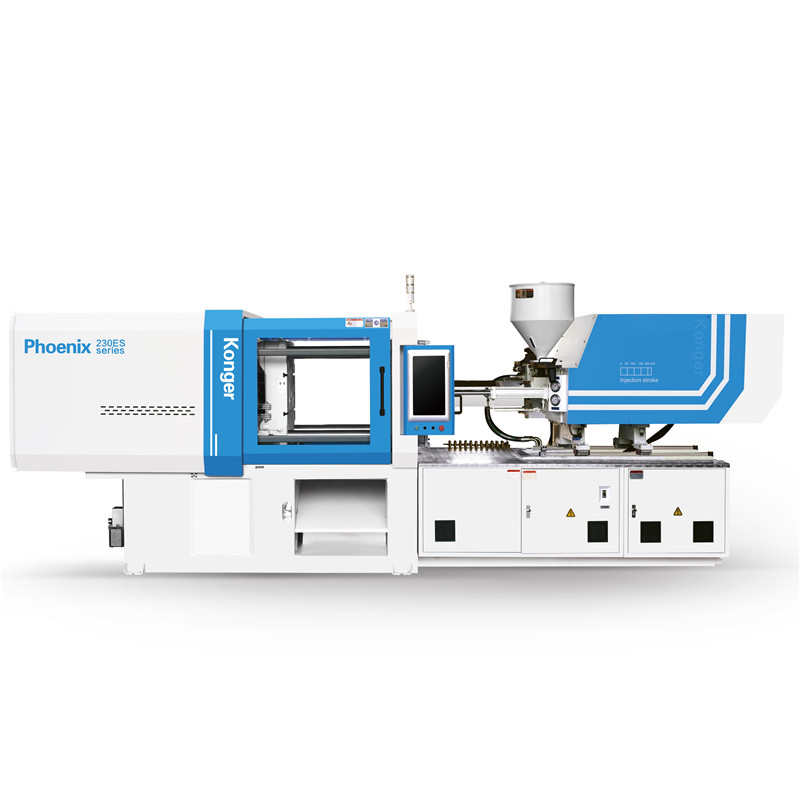

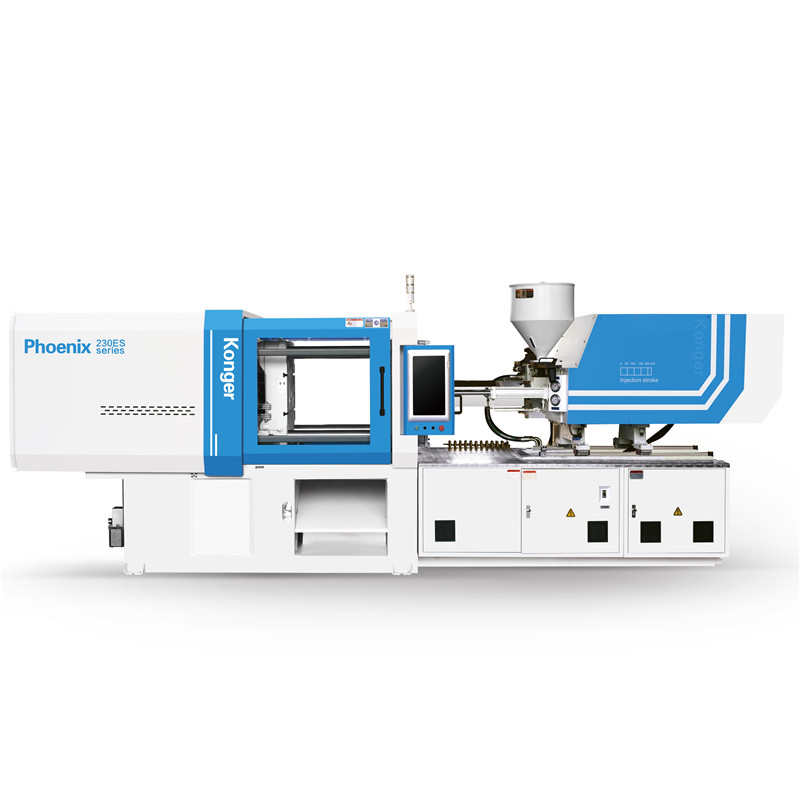

Phoenix-230ES Full High Speed Plastic Injection Molding Machine

The Injection unit is fully electric, and theinjection speed can reach 300-1000mm/s;Storage parts adopted high response, lowinertial servo motor with belt wheel drive screw structure, Not only can improve accuracy, but also energy saving. It can achieve compound action, shorten the molding cycle;

With finite element technical analysis platen design, optimizing platen structure, dedicated to fast operation, especially suitable for precision mold usage;

Adopting modular design,the same mold locking mechanism can combine with different specifications of injection mechanisms and screw.

-

K-TEC180/U Bakelite Series Plastic Injection Molding Machine

Specially designed screw & barrel for Bakelite, which is processed by high strength bi-metallic steel with the characteristic of anticorrosion and abradability.

Using the oil cooling device, in order to making sure the precision & stability of temperature control. Excellent design plasticity materials such as thebakelites,break the mould and exhaust function.

Replacing the screw&barrel,can change intothermoplasticity injection molding machines.

Increasing the injection rate and realize the effective and high-quality plastination by the bigger Pre-hydraulic pressure motor.

Specially designed the cladding device and temperature control interface of the both moulds which are controlled by the high-accuracy computer for the bakelite mould high-temperature’s requirment.

Realizing the direction control by using the high-accuracy E-ruler,which can reach by 0.1mm.

Automatically adjusting the mould function, can input directly the clamping force, has been finished the mold thickness adjustment by the computer.