-

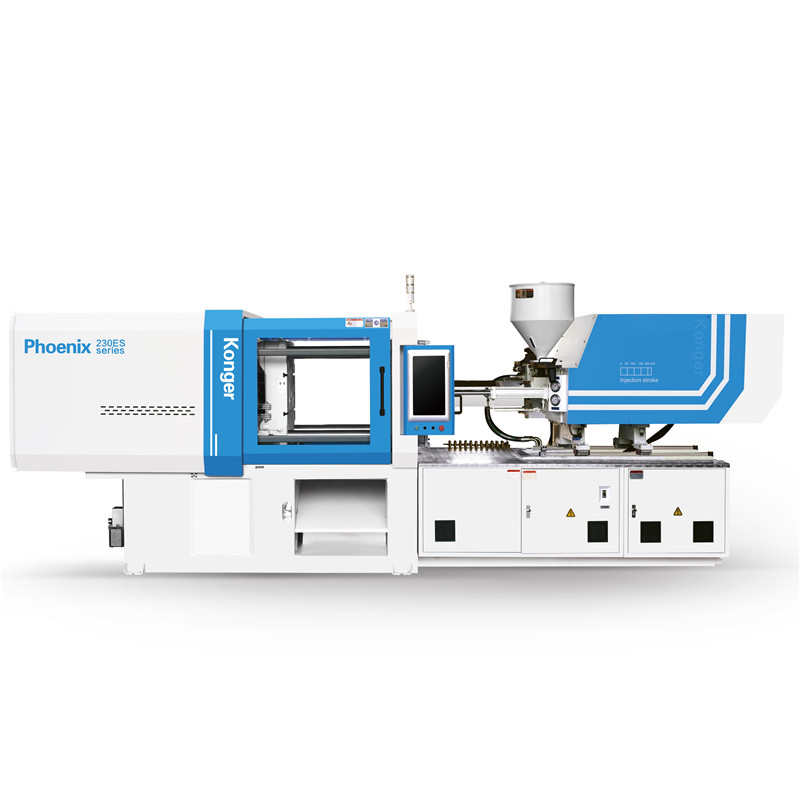

Phoenix-230P Half High Speed Plastic Injection Molding Machine

Compared with the traditional injection molding machine, Phoenix /P series has a faster injection speed, which can reach about 150mm/s. It can solve some defects of traditional injection molding machines in the injection process (such as water ripples,etc.);

Can meet customers’ high requirements for precision parts;

With finite element technical analysis platen design, optimizing platen structure, dedicated to fast operation, especially suitable for precision mold usage;

Adopting modular design, the same mold locking mechanism can combine with different specifications of injection mechanisms and screw;

Compared to traditional injection molding machines, it has greater output power.

-

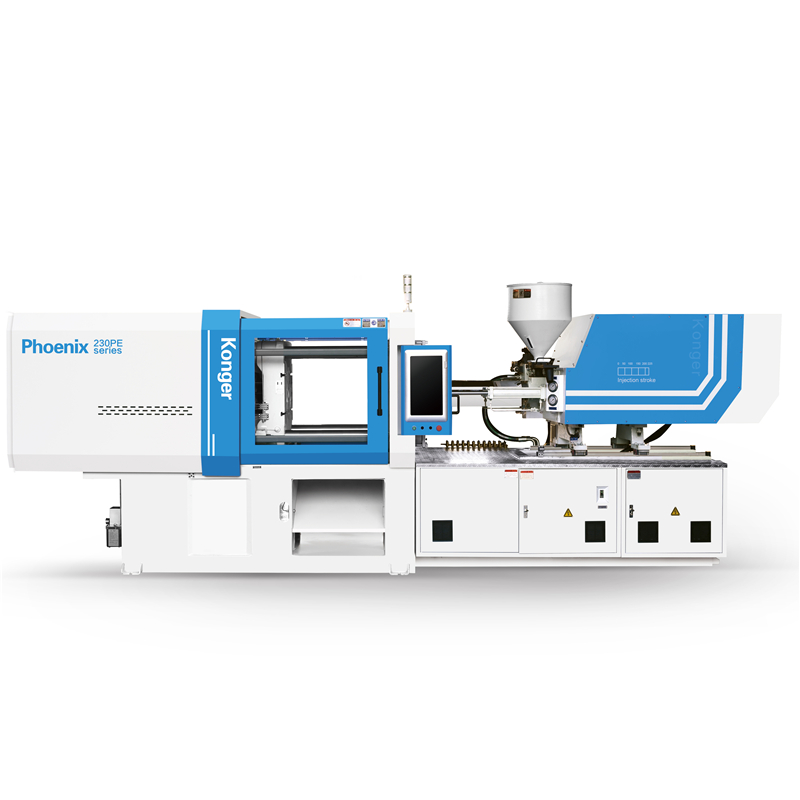

Phoenix-230PE Half High Speed Plastic Injection Molding Machine With Electric Charging

Compared with the traditional injection molding machine, Phoenix /P series has a faster injection speed, which can reach about 150mm/s. It can solve some defects of traditional injection molding machines in the injection process (such as water ripples,etc.);

Can meet customers’ high requirements for precision parts;

With finite element technical analysis platen design, optimizing platen structure, dedicated to fast operation, especially suitable for precision mold usage;

Adopting modular design, the same mold locking mechanism can combine with different specifications of injection mechanisms and screw;

Compared to traditional injection molding machines, it has greater output power.

-

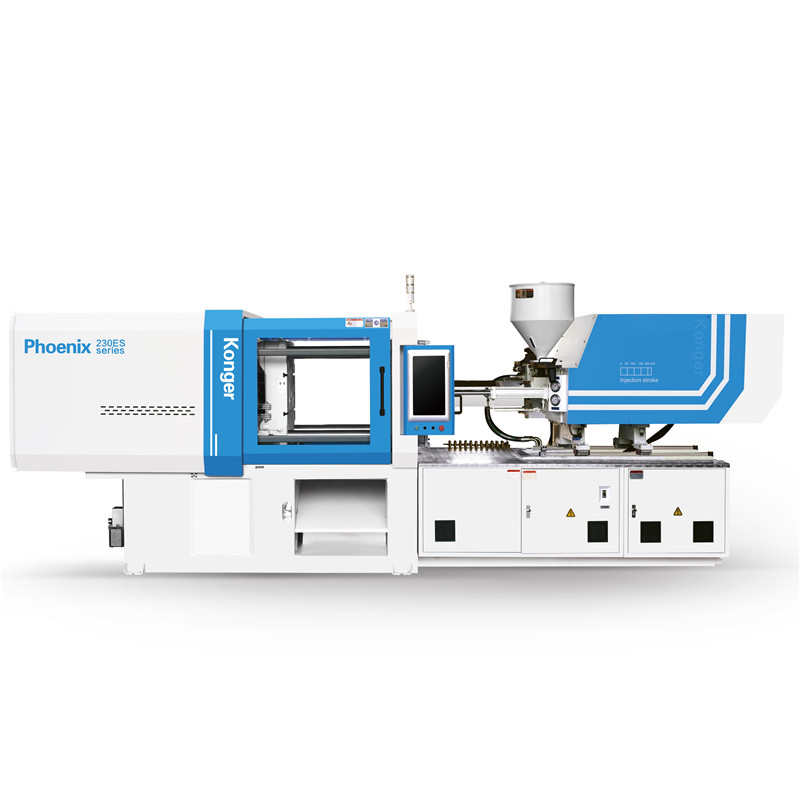

Phoenix-230ES Full High Speed Plastic Injection Molding Machine

The Injection unit is fully electric, and theinjection speed can reach 300-1000mm/s;Storage parts adopted high response, lowinertial servo motor with belt wheel drive screw structure, Not only can improve accuracy, but also energy saving. It can achieve compound action, shorten the molding cycle;

With finite element technical analysis platen design, optimizing platen structure, dedicated to fast operation, especially suitable for precision mold usage;

Adopting modular design,the same mold locking mechanism can combine with different specifications of injection mechanisms and screw.